If you’ve built long enough in Utah, Idaho, Wyoming, Oregon, or the broader Mountain West and PNW, you’ve seen it: Pavers or Patiostone rocking after the first winter, mud pushing up through joints, that efflorescence ghosting across clean installs, once-tight edges start spreading. These are the things that will have customers quietly questioning your workmanship, which will cost you in callback issues and future referrals.

Well, here’s the uncomfortable truth, the visible surface is rarely the problem. It’s the system beneath it. Most patio failures aren’t aesthetic failures. They’re mechanical failures. Hydraulic failures. Compaction failures. Drainage failures.

This guide is for contractors who want to think beyond “that’s how we’ve always done it” and start thinking like system designers. Once you understand the physics, you stop guessing.

And when you stop guessing, you trade your callbacks for referrals..

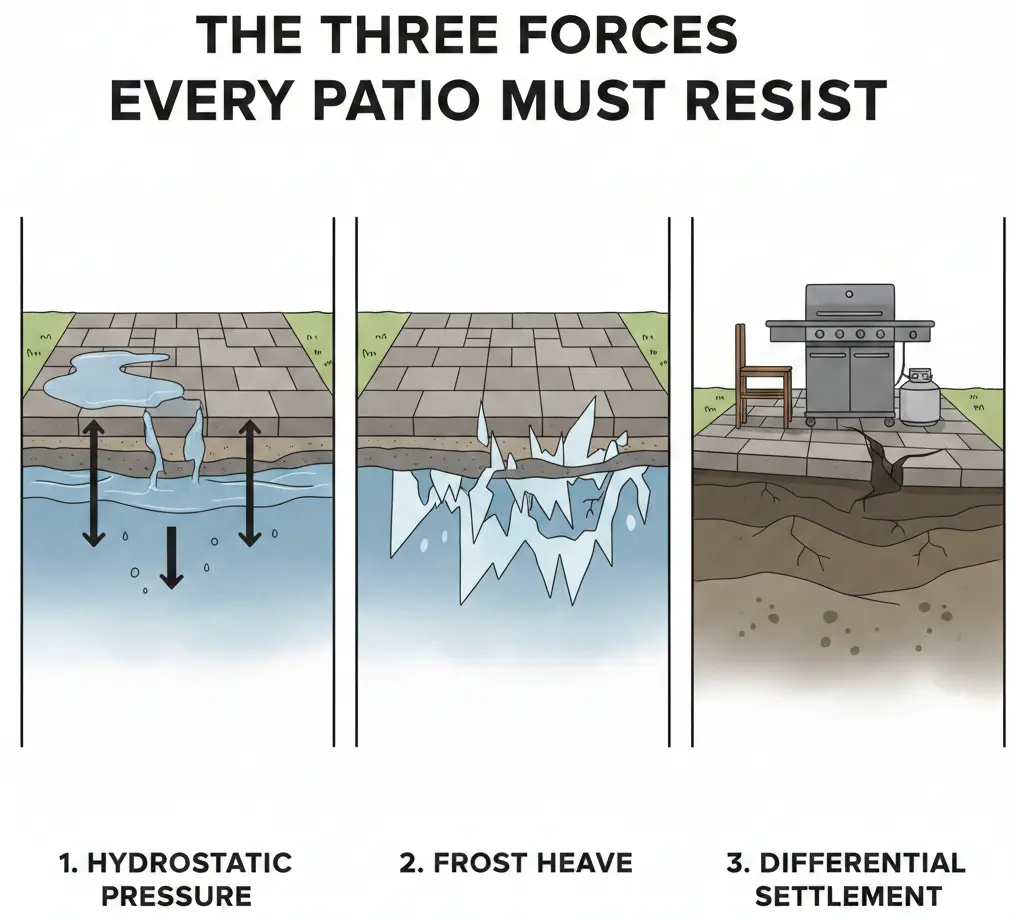

The Three Forces Every Patio Must Resist

Every hardscape system in our region is constantly negotiating three forces:

1. Hydrostatic pressure (water movement and saturation)

2. Frost heave (freeze–thaw expansion)

3. Differential settlement (load + soil variability)

Ignore one, and the others exploit it.

So, let’s unpack what’s really happening beneath your installs.

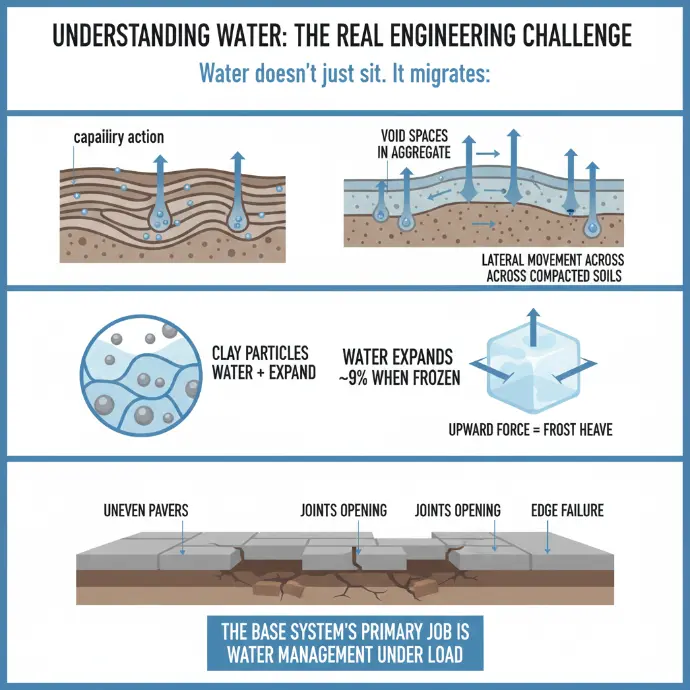

Understanding Water: The Real Engineering Challenge

Water doesn’t just sit. It migrates:

- Through capillary action

- Through void spaces in aggregate

- Laterally across compacted soils

- Upward through fine-grained materials

In clay-heavy soils common throughout Utah and parts of the PNW, water retention is amplified. Clay particles are microscopic plates that hold water in suspension. When saturated, clay expands. When frozen, that expansion increases further.

It’s important to keep this in mind: Water expands approximately 9% in volume when frozen. That expansion creates upward force, that upward force lifts your system, and that lift doesn’t always settle back evenly. Now you have uneven pavers, or joints opening, or your edges start failing.

The base system’s primary job is not just “support.” Its job is water management under load.

Subgrade: The Variable Nobody Controls (But Must Account For)

Native soils vary wildly across our service areas:

• Clay-dominant soils (high expansion risk)

• Sandy soils (low cohesion, high drainage)

• Silty soils (poor load distribution)

• Fill soils (unpredictable settlement patterns)

Before placing a single inch of base, you’re designing around soil behavior.

Here are some best practices for subgrade prep:

- Remove organic material

- Establish consistent elevation

- Compact in lifts (or layers)

- Address soft spots individually

- Use geotextile separation where soil contamination is likely

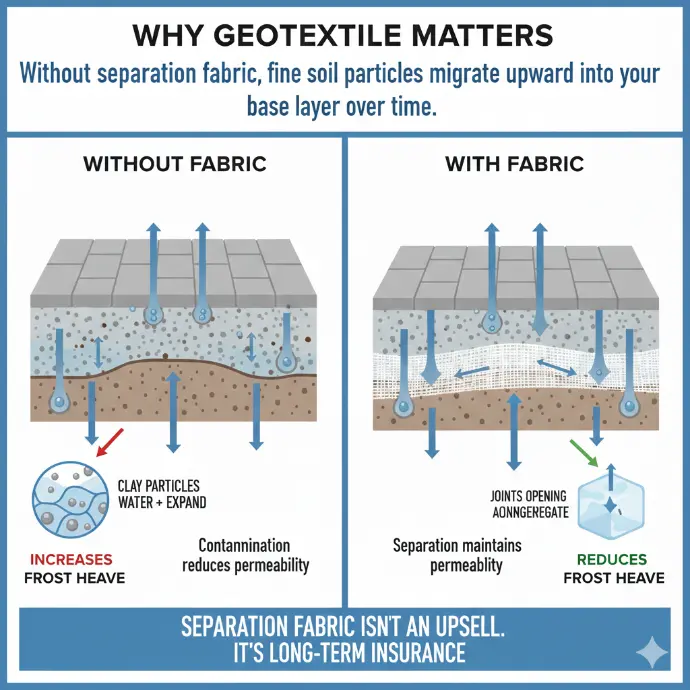

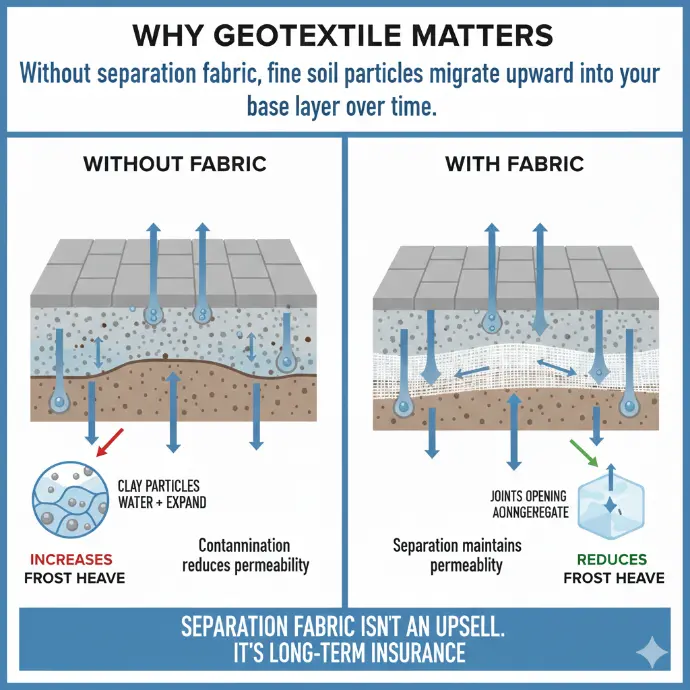

Why Geotextile Matters

- Without separation fabric, fine soil particles migrate upward into your base layer over time.

- This contamination reduces permeability and reduced permeability increases water retention.

- That increased water retention increases frost heave.

- Separation fabric isn’t an upsell. It’s long-term insurance.

Road Base: Structural Mechanics in Action

Crushed aggregate with fines (often referred to as road base) is engineered to:

1. Compact densely

2. Interlock under pressure

3. Distribute loads laterally

4. Maintain permeability (to a degree)

The angular shape of crushed stone creates mechanical interlock. When compacted in proper lifts, friction between particles resists movement. But compaction is not just about running a plate compactor once. True compaction requires:

- Moisture-balanced aggregate

- Lifts no greater than 3–4 inches

- Adequate vibration energy

- Proper edge confinement

Why Improper Compaction Fails

If base rock is not compacted in lifts:

- Lower layers remain loose

- Load transfers unevenly

- Settlement occurs gradually

- Surface irregularities emerge months later

Compaction isn’t about appearance. It’s about density.

Density determines load distribution and load distribution determines long-term stability.

Open-Graded vs Dense-Graded Base: Knowing the Difference

This is where engineering thinking separates average installs from excellent ones.

Dense-Graded Base (with fines)

Pros:

- Strong compaction

- Excellent load bearing

- Cost-effective

Cons:

- Reduced permeability

- Can trap water if not sloped properly

Open-Graded Base (clear crushed stone, no fines)

Pros:

- High permeability

- Excellent drainage

- Reduced hydrostatic pressure

Cons:

- Requires more material

- Must be designed intentionally

- Higher material cost

In high-moisture or freeze–thaw environments, open-graded systems dramatically reduce water entrapment. If water can move downward and away, frost heave potential drops significantly.

The question is not “Which is better?” The question is: Which is correct for this soil, this load, and this climate? That’s engineering thinking.

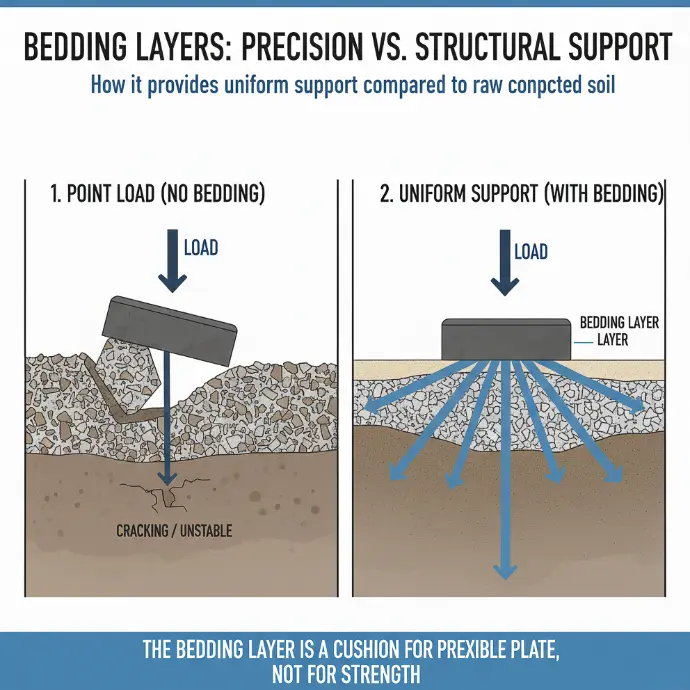

Bedding Layers: Precision vs Structural Support

Bedding material is often misunderstood. It does not provide structural strength. It provides surface precision. Its purpose:

- Minor leveling adjustments

- Surface uniformity

- Controlled interface between base and stone

The wrong bedding material introduces two major risks: Capillary rise (water wicking upward) and Particle migration (mud pumping).

Concrete Sand vs Masonry Sand

Concrete sand contains angular grains that resist shifting. Masonry sand is too fine and retains moisture. Fine particles increase capillary action. Capillary action draws water upward. When water rises into paver joints and freezes, joint failure begins.

This is why bedding choice matters more than most contractors realize.

Drainage Design: Intentional Water Movement

Water must be given a path. Slope should be:

- Minimum 1–2% away from structures

- Consistent across the surface

- Designed before excavation begins

Edge restraint is not cosmetic. It prevents lateral spread. Poor edge confinement allows horizontal creep. This leads to joint opening which invites water. Drainage is not just only about slope on top, it’s also about permeability below.

Load Distribution and Lateral Spread

Every patio experiences dynamic loads from the foot traffic, the furniture, potential vehicle loads and from the freeze–thaw cycling. When loads hit a properly compacted base, they spread outward through interlocking aggregate.

When base is loose or inconsistent, loads push downward, This downward pressure creates depressions that collect water. When you collect water you accelerate failures.

Mud Intrusion: The Hidden Contamination Problem

If you’ve seen joints darken or pump mud during heavy rain, you’re witnessing contamination failure. Here is what can cause it:

- No geotextile separation

- Poorly graded base

- Over-saturated bedding layer

- Improper compaction

Once fine soil migrates upward into base voids, permeability decreases. That area now behaves like clay. Now you’ve created a localized failure zone.

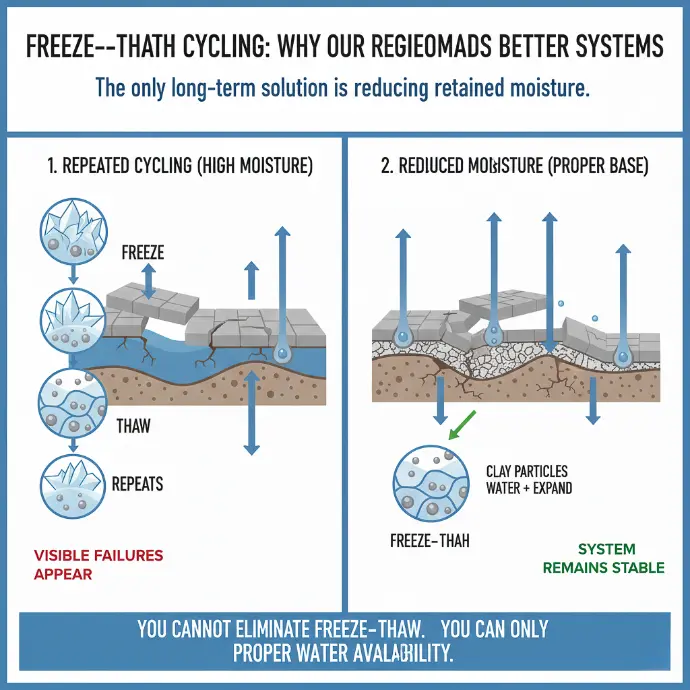

Freeze–Thaw Cycling: Why Our Region Demands Better Systems

The Mountain West doesn’t just freeze. It freezes. Thaws. Refreezes. Repeats. Each cycle expands trapped moisture. Each expansion stresses joints and bedding. With every repeated cycle it creates micro-movements. Micro-movements accumulate until eventually, visible failures appear.

The only long-term solution is reducing retained moisture. You cannot eliminate freeze–thaw.

You can only reduce water availability.

The Cost of Getting It Wrong

Callbacks cost more than materials, they cost you time, fuel, labor, reputation, and building that referral trust.

Contractors who master base systems:

• Close jobs easier

• Command stronger pricing

• Experience fewer warranty issues

• Sleep better in winter

Because they understand the system beneath the system.

Thinking Like a System Builder

Here’s the shift: Stop thinking in materials. Start thinking in systems.

Instead of: “What patio stone are we using?”

Ask:

“How is water moving through this install?”

“What’s the soil behavior here?”

“What’s the frost risk?”

“How is load distributed?”

When you think this way, your installs stop being decorative. They become engineered. And clients notice.

Where American Stone Fits In

We’re not here to sell you just road base or sand. We’re here to help you design the system correctly. That means talking through:

- Soil types

- Moisture exposure

- Drainage patterns

- Compaction methods

- Material compatibility

- Climate realities

Because building it right starts below the surface. Contractors who understand this are the ones who grow. Stone doesn’t fail. Systems fail. And systems fail when water, compaction, and drainage are treated as afterthoughts. If you’re expanding into outdoor projects, or leveling up your hardscape game, or just needing a refresher - master the base and everything builds from there. It’s not flashy. It’s foundational. It’s the difference between a patio that looks good for a season and a patio that performs for decades.

Build it right.

Build it once.

Wanna talk to a Sales Expert? Click here.

An Engineering-Level Guide for the Right Base Materials to Reduce Mud, Moisture, and Long-Term Patio Issues